新闻动态

产品新闻

查看更多

产品新闻

公司新闻

展会新闻

应用指南

产品中心

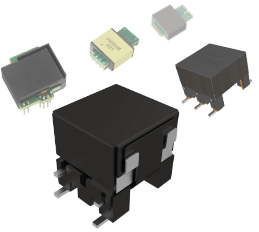

变压器

顺络电子变压器产品包括绕线变压器和平面变压器,采用全自动化产线生产,很好地应对整体性的劳动力短缺问题;产品性能优良,符合相关标准要求,质量稳定,一致性好,满足客户低缺陷需求,作为开关电源变压器、通讯变压器,大量应用于网络设备、安防、汽车电子、电源模组等。

查看详情

产品中心